Quand l’imprimante 3D permet de fabriquer un bois plus vrai que nature

Et si la technologie surpassait les lois de la nature ? Comme évoqué dans le concept « Quantum Alchemy » – Thème Multiverse du Cahier Influences SS20 (à partir de la page 86), le phénomène redouté, serait pourtant sur le point de devenir une réalité. Et pour cause, des ingénieurs de l’Université de Columbia ont réussi l’exploit de créer, grâce à une imprimante 3D, des blocs de bois au rendu ultra-réaliste.

Du bois d’olivier à une résine imprimée

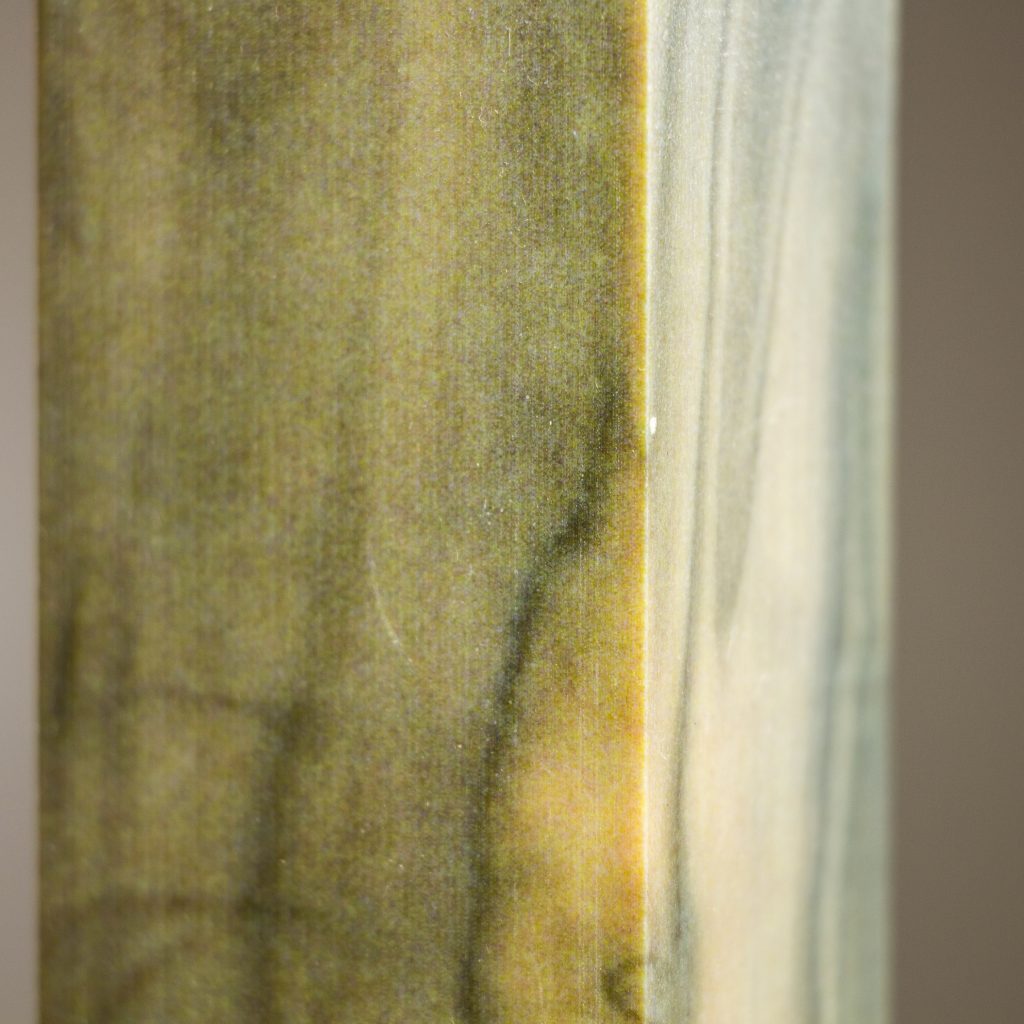

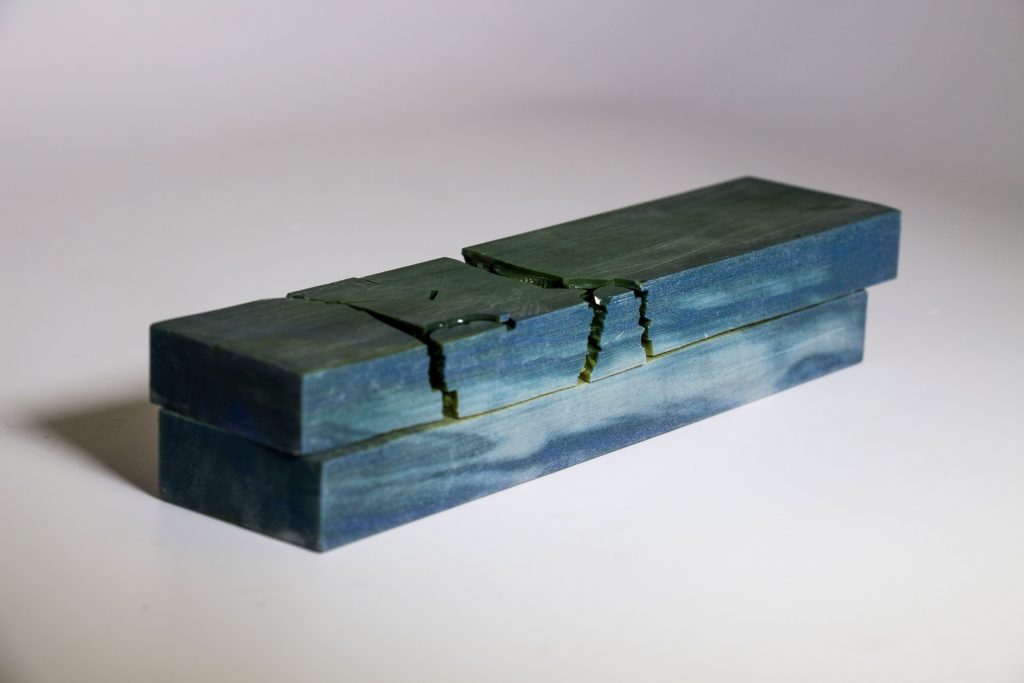

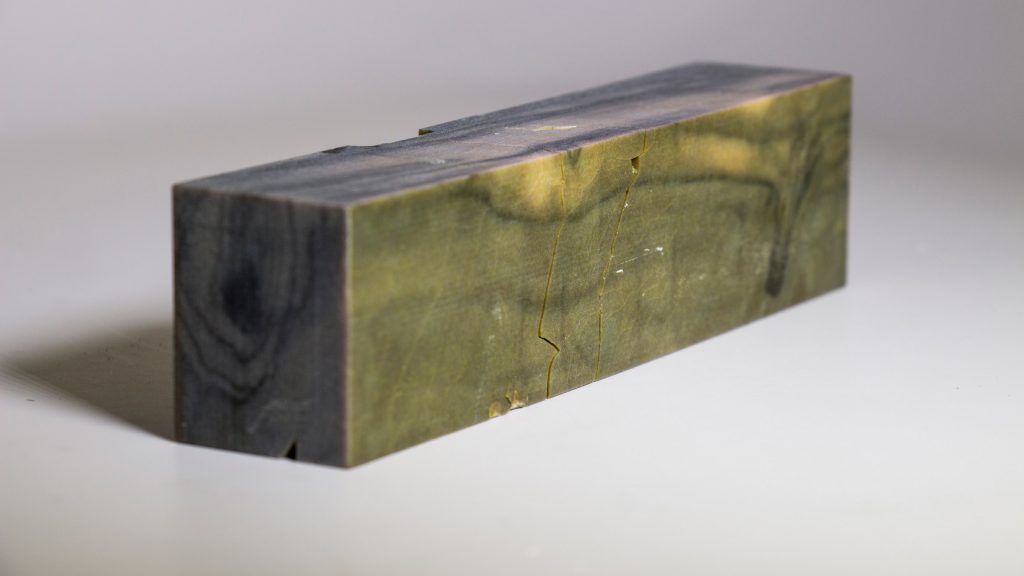

Grain, texture, nuances de couleur, le bloc de résine modélisé sur un échantillon de bois d’olivier ressemble à s’y méprendre au morceau original. “L’objet imprimé final se rapproche du bloc de bois d’origine, à la fois par son apparence extérieure et par son motif de couleur interne, comme le confirme le bloc lorsque celui-ci est coupé ou cassé”, ont-ils déclaré. Une réalisation scientifique inédite donc, que ces chercheurs doivent à des innovations récentes en terme d’imagerie numérique.

En effet, ils ont tout d’abord utilisé une forme d’imagerie tomographique destructive permettant de photographier des tranches de bois ultra-fines, coupées à seulement 27 micromètres (0,027 millimètres) de largeur par une fraiseuse CNC. L’ensemble des 230 images a ensuite été transmis à une imprimante PolyJet Stratasys J750, une machine hors du commun capable d’imprimer des couleurs et des matériaux variés à l’aide de voxels.

Le voxel, source de texture interne complexe

Équivalents des pixels, mais dans un espace 3D, les voxels sont les plus petits éléments dans lesquels un objet peut être divisé, dans le cadre d’un processus de conception. Avec l’impression voxel, les créateurs d’un objet donné peuvent spécifier chacune des caractéristiques qu’ils souhaitent y retrouver. Dans le cadre de ce projet, le Stratasys J750, l’équipe de l’Université de Columbia a déclaré avoir établi plus de 760 milliards de voxels possibles.

Les ingénieurs ont ainsi contrôlé la valeur de couleur de chaque point pour produire leur bois numérique. Par ailleurs, ils ont précisé que la même technique pourrait un jour être utilisée avec des propriétés de matériaux différentes, telles que la rigidité. De quoi imaginer d’infinies applications en matière de design et d’architecture.